The vibration system is mainly controlled by servo controller, low frequency feeding and high frequency molding. Vibration has 4 advantages: 1) fast response. The vibration acceleration time is less than 1s rapid prototyping, the vibration elimination time is less than 0.3s to eliminate the residual vibration effectively, speed up the molding and demoulding speed and improve the efficiency.

2) The vibration effect is good, and the energy consumption is low. The servo motor has high control precision and quick response, and each motor is independent unit. It has no interference with each other. It overcomes the energy cancellation and loss caused by mechanical synchronization of other vibration. The vibration effect is better and the energy saving effect is obvious.

3) Improve the production efficiency and reduce the damage of the equipment. Because of the fast vibration speed and short time, the molding cycle is shortened, and the damage caused by the long time vibration to the equipment is reduced, the service life of the equipment is prolonged.

4) The structure of the equipment is reduced. Because servo motors are independent units, there is no need for synchronous devices between them, so that the mechanical structure is reduced and the maintenance is convenient.

2. Servo vibration finger cart

The automatic finger cart has automatic rail positioning device, automatic line retracting device and real-time monitoring system. The servo control system is adopted in the walking and line collecting device. The high / low speed running is stable, and the closed loop control of position, speed and torque is realized, and the precise positioning is achieved. The safety of the production process is ensured.

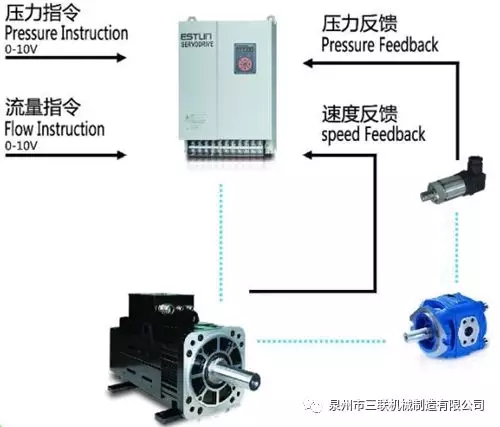

3. Servo hydraulic system

Servo hydraulic system makes the output of the system change quickly and accurately with the change of input quantity, and at the same time, the output power is greatly enlarged. High energy saving, fast dynamic response, high load stiffness, high precision and high power control are the unique advantages of servo hydraulic system.

4.Off-line cubing system

The off-line cubing system can run independently. Compared with the traditional cuber, the off-line cuber can be shared by many block machines, and it supports the automatic transformation of the traditional simple block factory. It is suitable for the stacking of the hollow block, solid block and pavement block in the production. The cubing system, under the control of SIEMENS PLC software programming, makes it automatic and intelligent. It can be stored in a rotating cross section for different specifications. It not only improves the work efficiency of the product palletizing, but also reduces the labor intensity of the workers, and reduces the cost of investment, and overcomes the defects of the limit of the site and the increase of the production cost. It is well received by the new and old customers

With the development of the market and the improvement of demand, the Sanlian Machinery will follow the pace of the times, work hard and make use of new technology in the process of R & D and production, fully improve production efficiency, exert manpower, material resources and realize high automation control, and make all the technical features of the equipment a bright spot for the Sanlian to attract customers.

.jpg)

.jpg)